Enhancing Metal Fabrication with Advanced Bending Technology

Introduction

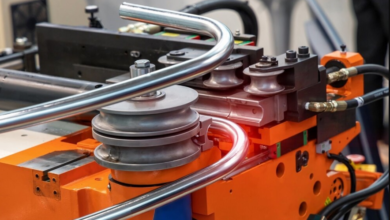

Metal fabrication has evolved rapidly in recent decades, with machinery becoming more sophisticated, precise, and efficient. Among these advancements, modern press brakes have emerged as indispensable tools for manufacturers. They allow for precise bending of metal sheets, enabling the production of components with complex geometries and tight tolerances. These machines have become critical in industries ranging from automotive to aerospace and construction.

The Evolution of Press Brakes

Traditional press brakes relied primarily on manual operation. Operators adjusted the bending angle by hand, which often led to inconsistencies and required extensive skill. As technology progressed, hydraulic and CNC-driven systems introduced automation, improving repeatability and efficiency. Multi-axis machines further enhanced control, allowing operators to manage multiple parameters simultaneously.

Understanding Multi-Axis Systems

A 4 axis press brake is a modern solution that balances complexity with user-friendliness. It provides independent control over the primary axes responsible for bending operations. This allows precise adjustments to the back gauge, ram, and other key components. Manufacturers benefit from consistent bends, reduced material waste, and the ability to tackle intricate projects with minimal manual intervention.

Key Features

- Independent Axis Control: Operators can adjust multiple points at the same time for precise bends.

- CNC Programming: Predefined bending sequences minimize human error and streamline production.

- Versatility: The machine handles various sheet metals and thicknesses efficiently.

- Safety Systems: Light curtains, emergency stops, and protective barriers ensure operator safety.

- Durability: A robust frame maintains stability during heavy-duty operations.

These features collectively improve productivity while maintaining high quality.

Advantages Over Conventional Machines

When compared to manual or single-axis machines, multi-axis press brakes offer several advantages:

- High Precision: Multi-axis control ensures accurate bending angles.

- Efficiency: Automation allows for faster production cycles.

- Reduced Waste: Accurate bends minimize scrap material.

- Ease of Operation: Less dependency on manual skill reduces operator error.

- Consistency: Each piece is produced uniformly, even in large batches.

These benefits make multi-axis machines ideal for high-demand manufacturing environments.

See also: The Financial Side of Building a Global Tech Company

Applications Across Industries

The versatility of modern press brakes allows them to be used in multiple sectors:

- Automotive: Producing brackets, panels, and chassis components.

- Aerospace: Fabricating lightweight, precise components.

- Construction: Shaping structural parts, metal enclosures, and facades.

- Electronics: Bending panels and enclosures for electrical and electronic equipment.

- Custom Fabrication: Ideal for prototyping and low-volume, high-precision projects.

By offering consistent and precise bending, these machines improve both the quality and speed of production.

The Importance of Multi-Axis Control

A 4 axis press brake enables manufacturers to tackle more complex designs with ease:

- Back Gauge Adjustments: Accurate placement of sheets for consistent bends.

- Independent Tool Alignment: Ensures precise positioning for complex geometries.

- Real-Time Corrections: CNC control allows for adjustments during the bending process.

- Complex Forming: Multiple bends can be performed without repositioning the material.

This capability enhances efficiency and reduces the risk of errors, particularly in high-volume production.

Selecting the Right Press Brake

Choosing the ideal machine requires evaluating several factors:

- Number of Axes: Consider the complexity of operations and required precision.

- Drive Type: Hydraulic, electric, or hybrid systems offer different levels of performance.

- Software Interface: Intuitive CNC programming simplifies operation.

- Build Quality: A strong frame ensures stability and durability.

- Service and Maintenance: Reliable support reduces downtime and improves longevity.

Proper machine selection ensures maximum productivity and return on investment.

Maintenance and Operational Best Practices

Maintaining optimal performance requires regular care:

- Routine Inspections: Check mechanical, hydraulic, and electrical components frequently.

- Lubrication: Keep moving parts properly lubricated to reduce wear.

- Software Updates: Ensure CNC systems are current for optimal operation.

- Operator Training: Skilled operators reduce errors and prevent machine strain.

Consistent maintenance increases lifespan and maintains precision.

Economic Advantages

Investing in modern press brakes can provide significant financial benefits:

- Reduced Material Waste: Accurate bends minimize scrap.

- Faster Production Cycles: Automation increases throughput.

- Lower Labor Costs: Reduced dependency on manual adjustments.

- Long-Term Reliability: Quality construction reduces maintenance costs.

The result is a more efficient operation and higher profitability.

Future Trends

Industry trends point toward greater integration of technology in press brake systems:

- Smart Manufacturing: IoT-enabled machines for real-time monitoring and analytics.

- Predictive Maintenance: Sensors anticipate issues before downtime occurs.

- Energy Efficiency: Electric and hybrid drives reduce power consumption.

- Automation: Robotic loading and unloading further streamline operations.

These trends will continue to enhance efficiency, precision, and cost-effectiveness.

Conclusion

Modern press brakes, particularly multi-axis models like the 4 axis press brake, have transformed metal bending operations. They offer precision, speed, and versatility that traditional systems cannot match. By carefully selecting the right machine, maintaining it properly, and leveraging its advanced features, manufacturers can optimize productivity, reduce waste, and produce high-quality components. The ongoing development of press brake technology promises even greater capabilities for the future of metal fabrication.