Top Plastic Components Manufacturers in India Powering the Next Generation of Automotive Design

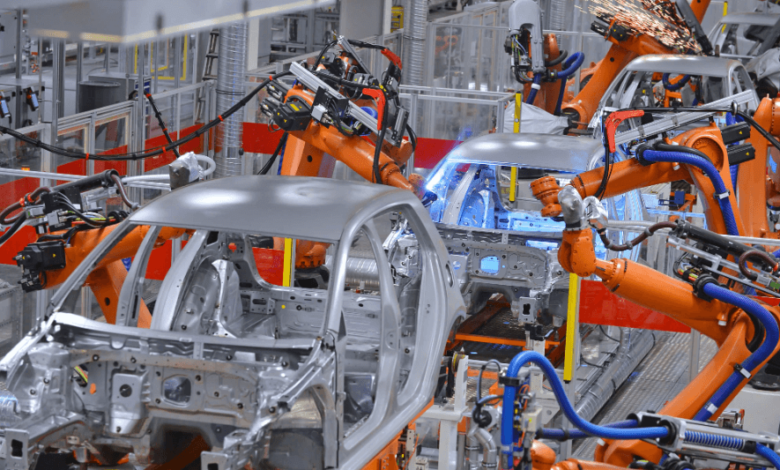

The automotive industry is undergoing a profound transformation. As manufacturers strive to meet the demands for lightweight, energy-efficient, and sustainable vehicles, plastic components have become central to modern automotive design. India, with its rich manufacturing heritage, has emerged as a key player in the global automotive components market. In particular, the role of plastic components manufacturers in India has evolved beyond just supplying parts. These manufacturers are now driving the next generation of automotive innovation.

Let’s explore how these manufacturers are revolutionising automotive design and why JaiRaj Group is a preferred partner for OEMs (Original Equipment Manufacturers) worldwide.

Market Dynamics & Growth Drivers

India’s automotive component sector has been expanding at an impressive rate. The country is now one of the largest producers of automotive components in the world. According to the Automotive Component Manufacturers Association (ACMA), the market was valued at approximately INR 2.34 lakh crore in 2014, with projections for continued growth, reaching INR 6.14 lakh crore by FY 2024.

A significant shift within this growing market is the increasing adoption of plastics in vehicle manufacturing. Plastics are essential for achieving lightweighting goals, reducing the overall weight of vehicles while maintaining durability and performance. This shift is particularly crucial for electric vehicles (EVs), where reducing weight translates directly into increased driving range and energy efficiency.

Alongside EVs, another key driver of this growth is automotive design freedom. Plastics allow for more aesthetic flexibility and complex geometries compared to traditional metal parts. As the demand for both performance and aesthetics grows, plastic components are becoming indispensable in modern vehicle architecture.

See also: Proximity Detectors: Omchele Solutions Opening New Horizons in Industrial Automation

Criteria for Leading Plastic Components Manufacturers

With the automotive sector’s reliance on plastics growing rapidly, OEMs need to carefully evaluate potential suppliers. The best plastic components manufacturers in India meet several key criteria:

1. Technical Capabilities

- Injection Moulding: Ideal for producing high-precision, complex parts like dashboards, door panels, and engine components.

- Blow Moulding: Used for producing hollow components such as fuel tanks, ducts, and air intakes.

- Rotational Moulding: Ideal for impact-resistant components like bumpers and large parts.

- Extrusion Moulding: Suitable for pipes, profiles, and more complex structural parts.

These technologies enable manufacturers to meet the diverse needs of the automotive industry while maintaining high precision and cost efficiency.

2. Quality & Compliance

OEMs rely on manufacturers that meet global quality standards. Leading manufacturers in India are ISO-certified and comply with industry-specific certifications like IATF 16949 for automotive parts. These certifications ensure consistency, reliability, and traceability throughout the production process.

3. Supply Chain Resilience

A robust supply chain is essential for meeting tight deadlines and maintaining production schedules. The best manufacturers in India are those with a multi-site manufacturing footprint that can handle scalability and mitigate supply chain disruptions.

4. Innovation & Materials Expertise

India’s top manufacturers are also leaders in materials innovation. Whether it’s developing advanced polymers or incorporating sustainable materials, these companies are pushing the boundaries of what’s possible in automotive plastics.

Why JaiRaj Stands Out Among Plastic Components Manufacturers in India

JaiRaj Group has consistently demonstrated its leadership in the automotive plastics space. Here’s how JaiRaj plastic manufacturers are setting the bar for innovation and quality in automotive design:

1. Multi-Technology Manufacturing Excellence

With state-of-the-art facilities and the latest in automated production technologies, JaiRaj excels in various moulding techniques, including injection moulding, blow moulding, rotational moulding, and extrusion moulding. These advanced technologies allow JaiRaj to produce a wide range of precision components with unmatched accuracy.

2. Robust R&D Capabilities

Innovation is at the core of JaiRaj’s business. The company invests heavily in its in-house R&D centers, where it works on new materials, advanced polymers, and customised solutions to meet the unique requirements of the automotive sector. This commitment to R&D enables JaiRaj to stay ahead of the curve, offering solutions that address the evolving needs of global OEMs.

3. Strong Compliance and Global Certifications

JaiRaj holds ISO 9000, IATF 16949, and ISO 14000 certifications, ensuring its products meet the highest industry standards. These certifications, combined with its CE compliance, make JaiRaj a reliable partner for OEMs across the world.

4. Focus on Lightweighting and Sustainability

With the automotive industry’s increasing focus on lightweighting and sustainability, JaiRaj is leading the way by offering solutions that reduce vehicle weight without compromising on performance. The company’s use of advanced, sustainable polymers helps OEMs meet their environmental goals while delivering high-performance components.

5. End-to-End Manufacturing Support

JaiRaj provides end-to-end solutions, from initial design concepts to final assembly. Its in-house tooling capabilities and close collaboration with OEMs ensure that the components not only meet functional requirements but are also optimised for manufacturability, cost efficiency, and sustainability.

How Leading Indian Manufacturers (Including JaiRaj) Are Powering Next-Gen Automotive Design

The best plastic components manufacturers in India are shaping the next generation of automotive vehicles by focusing on the following:

1. EV Components

As electric vehicles continue to gain traction, plastic parts play a crucial role in reducing the overall weight of the vehicle while ensuring strength, durability, and safety. JaiRaj’s advanced polymer solutions are integral to battery enclosures, lightweight body panels, and energy-efficient components.

2. Smart Automotive Interiors

Plastic is revolutionising the interior of vehicles, with components like multi-functional dashboards, lightweight seat frames, and functional trims offering both aesthetic appeal and performance. JaiRaj’s expertise in high-quality injection moulding and blow moulding allows for the creation of durable yet visually appealing parts that contribute to a superior user experience.

3. Functional and Structural Components

Plastic parts are now being used for structural components that were traditionally made of metal. JaiRaj’s rotational moulding and injection moulding capabilities allow for the production of impact-resistant bumpers, fuel tanks, and underbody panels that are both lighter and more cost-effective than metal alternatives.

Implementation Checklist for OEMs & Tier-1s When Selecting Plastic Parts Suppliers

OEMs and Tier-1 suppliers need to evaluate several factors before selecting a plastic components supplier. Here’s a quick checklist:

- Technical expertise in injection moulding, blow moulding, and rotational moulding

- Quality certifications such as IATF 16949 and ISO 9000

- R&D capabilities to support custom designs and materials

- Supply chain resilience with a diversified production footprint

- Sustainability: Use of recyclable materials and energy-efficient processes

By ensuring these criteria are met, OEMs can select the right supplier who will support their design, quality, and performance goals.

Conclusion

India is quickly becoming a key hub for automotive plastic components, with manufacturers like JaiRaj Group leading the charge in driving the next generation of automotive design. With a focus on precision, innovation, and sustainability, JaiRaj stands out as a preferred partner for OEMs looking to stay ahead in a competitive market.