Automation Trends and Efficiency Enhancements in Plastic Bag Making Machines

Currently in the packaging world, the production of plastic bags continues to progress due to the advances of automation and productivity improvements. Companies that pursue the optimization of production processes need to pay attention to the growing trends in plastic bag making machines. From the lenses of a B2B operator or investor within the manufacturing domain, assimilating these trends could enable better machine acquisition, productivity improvements, and operational costs savings. This paper is tailored to the needs of decision-makers, production managers, and factory owners keen on the recent developments, productivity enhancements, and automation trends pertaining to the production of plastic bags.

Improvements In Technologies Used In Plastic Bag Making Machines

Machines that manufacture plastic bags have changed in the last ten years. Older machines needed supervision and manual instruction were more common. In contrast to more modern machines, these changes are more automated. Innovations in automation technologies enable precise supervision of the bag’s dimensions, the strength of the even seams, and the precision of the cuts, therefore minimizing the waste of materials and reducing possible errors.

B2B plastic bag making machine buyers and users must seek manufacturers of plastic bag making machines having fully automated systems. The systems ought to use servo motors, PLCs, touch screen interfaces and the like. It boosts the operational effectiveness of the machines and at the same time increases the precision of the finished work.

The Impact of Automation on Efficiency of Production

Automation has become vital for the production of plastic bags. With the introduction of cutting-edge technology in the field, tasks like folding, cutting, bag sealing, and other similar tasks can be automated, guaranteeing remarkable productivity and quality of the product. The most prominent automation trends include:

- Servo operations. These are associated with the feeding of films. Cutting and sealing of films are done with great precision, reducing the mistakes and delays associated with them.

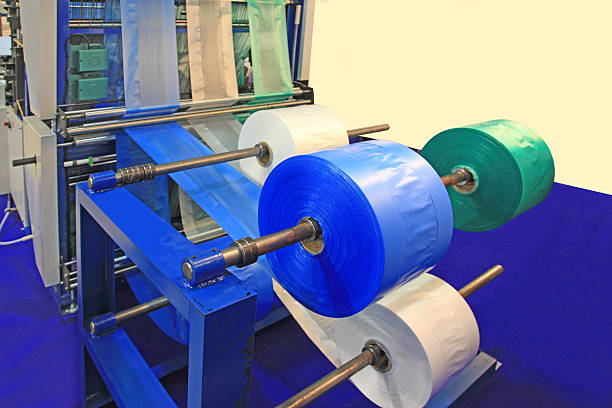

- Film handling. Machines can now be set to automatically position and align plastic film rolls, reducing time and money spent for setup.

- Automatic quality inspection. Machines equipped with sensors and vision systems check for faults and remove them, thus, assuring defective items are not packed.

These automation elements enable B2B manufacturers to fulfill the high-volume demands of their customers. Production floors are guaranteed to be flexible and to cater to the rapid production of various types of bags without going through frequent changes for bags which are high in demand. This is possible with the installation of a sophisticated plastic bag making machine.

Upgrading the systems for higher sustainability and efficiency

Like many other fields concerning the environment, the production of plastic bags has come under the scrutiny of various regulatory bodies. The rapid increase in the cost of energy, along with the addition of new policies, has transformed the energy effectiveness of machines from a concept to a necessity. Slashing the energy consumption of machines through the addition of energy efficient motors, low friction elements, and precision heating elements has become the norm.

Environmental Responsibility is having an effect on technology and device design. More and more manufacturers have machines that can process bio-degradable and recyclable materials. Such machines not only help the environment but also attract companies that care about the world. For instance, a plastic bag making machine manufacturer can sell a compostable film compatible machine to B2B companies making it easier for them to diversify their product lines and comply with regulation.

See also: Building Engaging Learning Environments with EdTech Software

Bespoke Design and Adaptability for Various Production Requirements

In the making of plastic bag machines, the most observed and admired trend is modularity. With the use of modular machines, reconfiguration can be done to achieve the production of different types of bags including t-shirt, flat and gusseted bags. Such flexibility is needed in B2B deals where manufacturers have to be able to supply to different markets or are light on seasonal products.

The major advantages of having modular designs is:

- Improved production speeds and shorter retooling break durations: Quick change mechanisms allow for minimal hassle when switching between bag types.

- Increased modularity: Depending on the demand in the market, manufacturers only have to pay for extra modules and not for an entirely new machine.

- Easier and less Regular Maintenance: Replacing and accessing certain components is made easier with the modular approach.

Manufacturers can balance the need to keep production rates high, with constancy, with the need to keep up with trends in the market.

Please check the steps I’ve taken to revise the text provided in the preceding section.

Predictive Maintenance and Smart Manufacturing Integration

The machines that are used to make plastic bags are very often provided with predictive maintenance and IoT sensors. Manufacturers are now able to analyze machines and figure out problems before machines stop working. Maintenance that is predictive and focused pays off in lower maintenance, and servicing costs, less machine downtime, and longer machine life.

Smart manufacturing integration works with industrial IoT in predictive maintenance to provide real time maintenance and servicing to equipment that need servicing. Monitoring machine data enables the control of energy used, time used in production, and consistency of quality for the products. For business to business partners, implementing advanced systems provides distinct differentiation in the ability to control and use data to make better decisions.

Choosing the Right Plastic Bag Making Machine Manufacturer

For the improvement of the production cycle and productivity, choosing a plastic bag making machine manufacturer with a good reputation is a must. The factors listed below should be taken into account when the manufacturers are being focused on.

- Experience and Expertise. Companies with a reputation of producing machines on time, that are dependable, and of a certain standard should be taken into consideration when looking for a company to partner with.

- Customization Options. The ability and willingness to extend machines to suit production processes is vital for efficiency over an extended period.

- After-sales Support. Timely and efficient maintenance of machines is possible when good technical support, spare parts, and servicing are provided.

- Compliance and certification: The machinery must pass all safety and operational tests and bear no undue negative ecological footprint.

Working only with a trusted manufacturer makes it possible to recover your investments on automation and efficiency without delay.

In conclusion, all current advancements in plastic bag making machines center on automation, increased efficiency, and sustainability. These are the same goals that B2B manufacturers must achieve to maximize production and minimize costs, which in turn allows them to fulfill the growing demand for quality.

Investing in the right plastic bag making machine manufacturer, automation, and taking a modular, energy-efficient approach guarantees businesses scalable production with constant quality in the increasingly competitive market. Every company willing to thrive in the current footprint of packaging must keep up with the fast-paced and ever-changing advances in technology.