Features Of The High Resolution Electronic Pressure Regulator

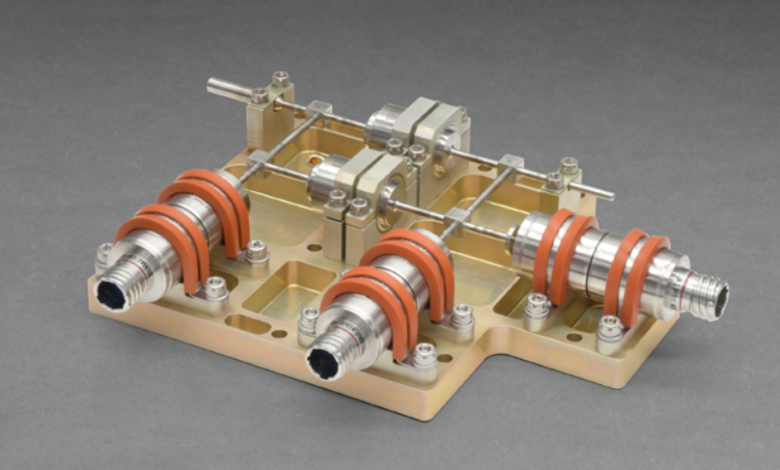

The high resolution electronic pressure regulators are efficient devices to regulate the pressure of gases or fluids. It is used in different industrial and scientific applications to increase precision and accuracy. The electro pneumatic regulator offers precision and automation in maintaining pressure within a desired range. This allows the production of products to your standardization

The pressure regulator offers precision and automation in maintaining pressure. These are designed to maintain a consistent pressure to control the flow of liquids. The closed-loop control systems mean they continuously measure and guage the pressure in a specific range.

High Resolution Electronic Pressure Regulators:

Various features and applications of the pressure regulator are described below:

1. Pressure Regulation:

Electronic proportional pressure regulators are designed to maintain consistent pressure levels within a set range. These regulators have a digital display and a pressure sensor for measuring the pressure of the gas or fluid. This is the main reason for installing the digital regulator in place of the mechanical regulator.

The electronic pressure controller has the following benefits:

- HREPCs have digital displays to provide real-time information for the current pressure and setpoints of the flow of liquid

- High resolution electronic pressure regulators are equipped with pressure sensors that measure the pressure of the flowing liquid and gases. These sensor data are used for feedback and control of the flow.

- Closed-loop control systems mean they continuously measure and guage the pressure in a specific range.

- Used in different industrial and scientific applications to increase precision and accuracy.

See also: What Is a Residential ESS and Why Is It Important for Modern Homes?

2. Digital Display:

The high resolution electronic pressure regulators have digital displays that provide real-time information. Current pressure, setpoints, and other relevant data are displayed on the screen. This allows setpoints to the current pressure and displays the measurements relative to pressure flow.

3. Pressure Sensors:

These controllers are equipped with pressure sensors that measure the pressure of the gas or fluid. This sensor data is used for feedback and control. The digital displays provide real-time information for the current pressure and setpoints of the flow of liquid.

4. Setpoint Control:

The high resolution electronic pressure regulator can set the desired pressure range. It ensures that the pressure stays within that range. It is adjusted manually or through digital interfaces and can be displayed for real-time monitoring.

| Features | Applications |

| Precise regulation of pressure | Laboratory Research for chromatography, mass spectrometry |

| Digital display for real-time monitoring | Manufacturing (semiconductor, pharmaceutical, food processing) |

| Pressure sensors for measurement | Automotive Testing (engine testing, hydraulic systems) |

| Setpoint control for the desired range | Oil and Gas Industry (drilling, well testing, production) |

| Closed-loop control for continuous adjustments | Aerospace (testing, simulation, pressure control) |

| Automation for hands-free operation | Environmental Monitoring (air quality, emissions) |

Conclusion:

Electronic pressure controllers are used in various industries due to their usability. Especially in the research fields, precise control and monitoring of pressure are crucial. For processing efficiency, managing the product quality, and the safety of the types of equipment. These valves offer features that enable accurate pressure regulation. These values are used in a wide range of applications and processes.