How custom lighting solutions improve your project results

Overview of modern LED lighting needs

You work with lighting projects that demand stable output and clean installation. LED products help you meet these needs because they support long life, low energy use, and compact design. Every project brings its own conditions, so you choose products that match the real environment instead of relying on one option for everything.

Key factors you check before choosing LED products

You measure brightness. You confirm voltage. You check the layout. You look at color temperature. You review build quality and heat performance. These steps help you avoid delays and unexpected replacement costs.

How product quality affects long term performance

Strong LEDs depend on chip quality, PCB strength, and clean assembly. These elements reduce dimming and color shift. You get stable performance because the product manages heat and electrical load effectively.

Why consistent brightness matters in large installations

Large spaces show every detail. Uneven brightness creates visible breaks. Clean and even light gives your project a more professional finish. It also helps you meet the expectations of commercial clients who need uniform results.

The role of heat control in stable LED output

Heat reduces LED lifespan. Good thermal design keeps the chip stable and protects brightness. It also helps prevent early failures. When products stay cool, your maintenance cost stays low.

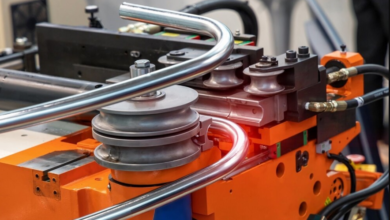

In the middle of planning a curved layout or long run installation, you often check how much bending a strip can handle and how cleanly it cuts. A flexible led strip lights factory supports you here by offering products that match tight spaces and complex shapes without losing brightness or stability.

Ways to evaluate product reliability with real project examples

You can run sample strips for long hours. You can compare color accuracy with your design materials. You can mount a small test setup to see output at different angles. Real testing gives you clarity before you place a full order.

How modular lighting options support different applications

Modular solutions help you work with fixed layouts and repetitive structures. You get consistent sizes and stable connectors. This makes installation faster. It also reduces mistakes because you rely on known dimensions.

What you should look for when comparing LED modules

You check lens design for brightness spread. You check chip type for output consistency. You check wiring for safe handling. You review diode spacing for smooth light coverage. You also confirm waterproof ratings for outdoor or humid areas.

In the middle of choosing modules for backlit panels or signage, you look for stable coverage without hot spots. The Best led module supplier helps you achieve this by maintaining even output and controlled spacing. This supports clean results in detailed projects.

See also: How Is Smart Technology Changing Excavator Operations?

Steps to select the right lighting solution for architectural and commercial use

You start with a layout plan. You measure every bend and open section. You choose brightness levels that fit the space. Cool white works for workspaces. Warm white works for restaurants. Neutral white supports retail displays.

You check if the project needs waterproof protection. You add aluminum channels when the client wants a clean finish. You pick dimming or control systems when needed. Each step keeps the installation smooth and predictable.

Closing content

Custom lighting solutions help you deliver accurate work. You choose products that match real conditions. You reduce installation errors. You save time. Your final output looks consistent and stable because the lighting performs as expected. When you select products with strong components and reliable heat control, you improve long term results and maintain trust with your clients.