The Role of Skilled Professionals in Modern Metal Bending

Introduction

In today’s competitive manufacturing industry, precision and consistency are key factors for success. Among the most important professionals contributing to this goal is the press brake operator. This individual plays a vital role in shaping metal sheets into precise components used across industries such as construction, automotive, aerospace, and electronics. The work requires not only technical knowledge but also a strong understanding of materials, machine operation, and safety protocols.

Understanding the Responsibilities

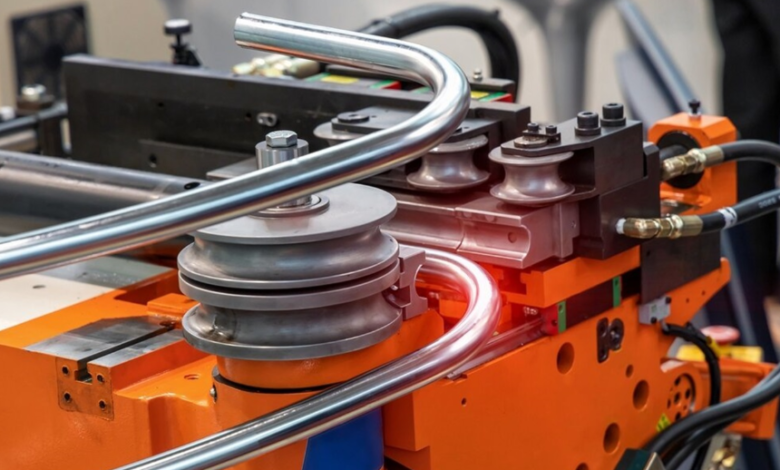

A press brake operator is responsible for setting up, operating, and maintaining the press brake machine, which bends and shapes sheet metal into specific designs. The operator reads blueprints and engineering drawings to determine the required dimensions and angles. After setting up the machine with the correct tooling and back gauge positions, they perform test runs to ensure accuracy. Each bend must meet the exact specifications provided in the design, requiring keen attention to detail and technical precision.

See also: Interior Basement Waterproofing Techniques for Long-Lasting Protection

Required Skills and Competencies

This role demands a combination of mechanical knowledge, computer literacy, and problem-solving abilities. A skilled press brake operator must understand how different materials behave during bending. For instance, stainless steel may require different pressure and angle adjustments compared to aluminum. They must also be proficient in using CNC (computer numerical control) systems that guide the machine’s movements. Communication and teamwork are equally important, as operators often collaborate with engineers, quality inspectors, and other machine operators.

Importance of Technical Knowledge

The work of a press brake operator extends beyond pushing buttons. It involves an in-depth understanding of machine calibration, die selection, and programming. Operators must know how to adjust the ram depth, back gauge position, and bending speed to achieve precise results. They also ensure that each part meets quality standards and inspect the finished products for accuracy. Any deviation can lead to wasted materials and production delays, which makes their technical expertise crucial.

Safety and Best Practices

Working with a press brake involves press brake operator potential hazards, so following safety protocols is essential. Operators must wear personal protective equipment such as gloves, safety glasses, and steel-toe shoes. They also ensure that all safety guards are in place before operating the machine. Proper training on emergency stop functions, machine lockout procedures, and safe handling of metal sheets reduces the risk of injury. Regular inspection and maintenance of the press brake also prevent mechanical failures and accidents.

Training and Certification

Most employers require a high school diploma or equivalent, along with specialized training in metal fabrication or CNC machinery. Many press brake operators receive hands-on experience through vocational schools or apprenticeships. Certification programs from recognized institutions add value to their career and validate their skills. Continuous learning is also encouraged since modern press brakes are becoming more advanced with computerized controls and digital interfaces.

Challenges Faced in the Workplace

Despite advancements in technology, the job still presents challenges. A press brake operator must deal with tight deadlines, material inconsistencies, and frequent machine adjustments. Fatigue can impact concentration, which makes attention to safety and accuracy even more critical. Another challenge lies in keeping up with rapidly evolving technology, as newer machines often require updated software knowledge and technical adaptability.

Impact of Automation and Technology

The integration of CNC systems has transformed the traditional bending process. Modern machines allow operators to input digital instructions, resulting in precise and repeatable bends. This has improved efficiency but also increased the need for skilled operators who can program, troubleshoot, and maintain these advanced systems. Rather than replacing workers, automation has enhanced their capabilities by reducing manual labor and increasing precision. The role of a press brake operator has evolved from manual handling to a more technical and analytical position.

Career Growth and Opportunities

The demand for experienced operators continues to grow in manufacturing sectors worldwide. With experience, a press brake operator can advance to supervisory roles, quality control positions, or CNC programming. Some professionals transition into engineering or production management after gaining sufficient technical experience. The combination of skill, precision, and problem-solving ability makes this career both stable and rewarding.

Conclusion

A press brake operator is a key contributor to the success of any metal fabrication process. Their expertise ensures that every bend, fold, and angle is accurate and consistent. The integration of technology has made their role more efficient and sophisticated, highlighting the importance of continuous learning and adaptability. As manufacturing continues to embrace automation, skilled operators will remain essential for maintaining quality, precision, and safety in every project.