Proximity Detectors: Omchele Solutions Opening New Horizons in Industrial Automation

Automation in the industry is a competitive arena. For successful and sustainable operations, utmost precision and efficiency, as well as safety, is a must. One such technology that helps in process optimization, at which accuracy is very important during operations, is proximity detectors. These devices help in managing and controlling production and assembly lines, robotic systems, as well as safety operations, and all without any physical contact. B2B Companies looking for dependable and high performing systems and devices, Omchele has advanced proximity detector systems that boost precision and optimize the manufacturing operations. More information about Omchele advanced proximity detectors can be found here.

What is a Proximity Detector?

Electronic sensors which identify whether an object is present, in a certain position, or is absent without having to make physical contact with it, are called proximity detectors. These devices can identify an object without physical contact unlike most whose engagement is mechanical, using devices that rely on, and construct electromagnetic fields, are capable of capacitance, can utilize light or any source of light, or use magnets and magnetic forces. Proximity detectors are contactless, making them very accurate in terms of efficiency, and, in the industrial arena, very durable, and, especially in high-speed or hazardous set-ups, very reliable.

For businesses, proximity detectors are crucial for sustaining processes, monitoring quality, and ensuring safety at the workplace. Integration of proximity detectors into automation systems facilitates businesses in lowering the downtimes, increasing outputs, and decreasing the chances of expensive mistakes. Omchele provides complete and reliable solutions for diverse businesses in the automotive, electronics, packing, logistics, and robotics industries.

Varieties of Proximity Detectors and Their Use in Industries

For each industrial application, a specific type of sensor is designed. Most Used proximity detectors are:

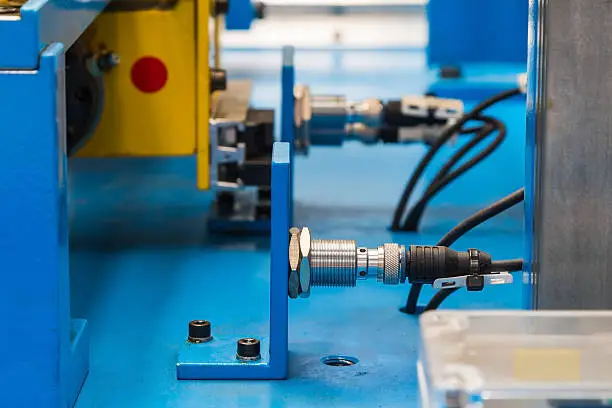

Inductive Proximity Detectors

They use electromagnetic fields to sense the presence of a metallic object. They find application in automotive, CNC, and industrial robotics due to their ability to survive in extreme conditions.

Capacitive Proximity Detectors

They are suitable for industries like food processing, packing, and material handling owing to their ability to sense metallic and non-metallic objects, such as plastics, liquids, and powders.

Photoelectric Proximity Detectors

These receivers use light beams to sense an object. They are highly useful in conveyor belts, packers, and robotics due to their ability to function over long distances. Omchele offers a wide selection of https://www.omchele.com/fr/switching-power-supply/ for B2B companies to enjoy unmatched dependability and precision.

- Magnetic Proximity Detectors

This category classifies products which detect magnetic fields for use in security systems, access control, and, most importantly, in monitoring industrial equipment.

Omchele’s portfolio comprises all these different categories enabling them to select the most suitable proximity detector for the specific operational issues of the business.

Benefits of Proximity Detectors for B2B Operations

There are immense advantages of incorporating proximity detectors in industrial businesses.

- Non-Contact Detection: Non-Contact detection systems stop mechanical wear, which in turns increases the longevity of the machinery and the sensors.

- High Accuracy: Better tracking of the sophisticated parts, materials, and components reduces the chances of error in a process.

- Increased Productivity: Process automatization improves efficiency on detection, reduces detection time, and decreases workflow stagnation.

- Safety Assurance: System detects workers or other physical objects in danger zones which minimizes the chances of incidents in the workplace.

- Flexibility: These systems can be designed for high-speed production, bulky machinery, or precise automated packing.

In return, the B2B companies are able to cut operational expenses, improve product uniformity, and amplify overall productivity. Sustainable industry growth in Omchele’s case will come from the proximity detectors which offer lasting industry value.

See also: How Is Smart Technology Changing Excavator Operations?

Applications of Proximity Detectors in Industry

Proximity detectors in industrial automation become increasingly important with every passing day. The primary uses of industrial proximity detectors are:

- Automated Manufacturing: Precision In lines with Synchronized Support And harmony Avoiding alignment and waste of parts.

- Robotics: Enhancing Awareness Of The Surrounding In Order To Move Accurately And Avoid Collisions.

- Packaging and Logistics: Supervising And Ensuring An Uninterrupted Flow Of Materials By Monitoring Items Flying On Conveyors To Avoid Jams.

- Quality Assurance: Ensuring Capture And Embedding Materials And Parts On The Work Table To Avoid Defective Goods During The Production Process.

- Employee Safety: Automatic shutdown of machines in the presence of Workers or Obstructions to Dangerous Parts.

Many B2B companies appreciate the ability to leverage improved quality of their products/ services due to the decreased operational risks and improved productive workflows. Omchele detectors are designed to accommodate all these range applications, from small automation systems to complex industrial set up.

Steps To Choosing The Most Suitable Proximity Detector

Another Business aims to achieve maximum efficiency, ROI and Value from their detectors should consider several factors.

- Target Material: Any metal objects should be detected by inductive sensors, while plastics should be equipped with capacitive or photoelectric sensors.* Range of Detection: Confirm that the detection distance is of no less than the minimum operational requirements and, more so, in large spaces, or rapidly moving environments.

- Working Environment: Less delicate sensors that can withstand dust, extreme temperature, moisture, or chemicals is a must.

- Reacting Time: in any instance of a high-speed production line, the detectors need to have a very fast response in order to avoid the line to bottleneck.

- Propitiatory Systems Compatibility: Check the installed automation systems and ensure the detectors can easily connect with other parts of the systems such as PLCs and other robotics.

All B2B clients of Omchele have the choice of using the consultancy and technical support in choosing and integrating the most appropriate proximity detectors into their systems. By using these systems companies will be able to enhance the level of productivity and safety while also reducing risks.

Advances in proximity detectors have most come with the changes in Industrial Automation. Major changes detected are.

- Increased Detection Sensitivity: more sensors are and will be connected to IoT and other numerous systems that will allow monitoring and even predictive maintenance.

- Decreased Dimensions: the smaller and more compact a sensor is, the more readily it can be applied into systems where space is at a premium.

- Increased Resistance Levels: these include high temperatures, extreme vibration, or other chemicals that might be intrusive.

- Reduced Consumption: the next detectors in line are predicted to support the need for less power in Industrial systems to meet the corporate level sustainability goals.

For B2B companies, focussing on these trends is a must for continued competitiveness and adaptability. Omchele remains at the forefront of proximity detector technology, providing timely solutions to industrial changes that are ready for the future.

In the industrial automation ecosystem, proximity detectors are key to achieving industrial automation due to their precision, ruggedness, and versatility. B2B companies can partner with Omchele to meet their goals of operational efficiency, increased safety, and sustained growth with a suite of advanced proximity detectors. To improve your industrial operations, look at Omchele’s collection of photoelectric proximity detectors to increase the efficiency of your operation.